Release time:2022-11-18

Plastic electrical boxes, sometimes called junction boxes, have plenty of pluses, including low cost, convenience, and ease of installation. But they're not the best choice for every application. When plastic doesn't make sense, the standard alternative is a metal box. Both plastic and metal boxes come in a full range of types and sizes for both indoor and outdoor applications.

Plastic boxes are nonconductive, which means they won't conduct electricity if they're touched by a live wire. Having a nonconductive box is good in most cases, but in some electrical systems it can create a problem. The nice thing about nonconductive boxes is that they don't need to be grounded. That is, they don't need a ground connection to the box itself. By contrast, metal boxes, which are conductive, must be grounded to the circuit grounding system, usually with a short wire called a pigtail that connects the box to the circuit's ground wire(s).

Where a nonconductive box creates a problem is in a system that uses metal boxes and metal conduit, rather than ground wires, to provide the system ground. If you replace an old metal box with a new plastic box in this type of system, you break the ground connection.

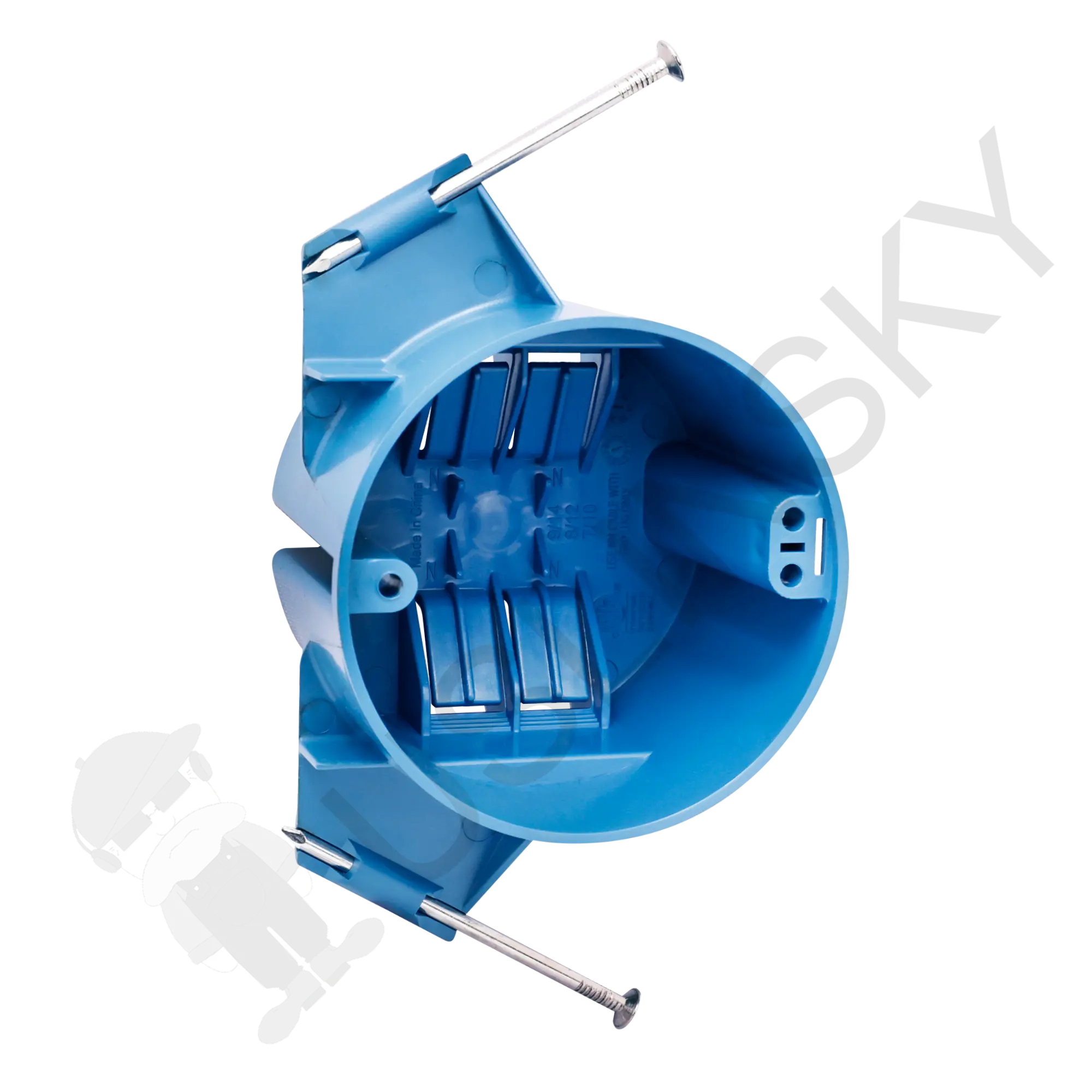

Plastic junction boxes are easy to install in many situations. They're easiest to install during new construction when the wall studs or ceiling joists are exposed. You simply hold the box against the wood framing and drive the two nails that come pre-attached to the box. They even have markings on the side for setting the proper depth so that the box is flush with the face of the wall when the drywall goes up.

Boxes for new construction are called "new work." There are also special boxes for remodeling work, called "old work." These have little ears that flip out to grab the backside of the drywall when the box is screwed in place. Metal boxes also come in old work types, but they aren't always as easy to use.

Some plastic junction boxes have integrated cable clamps, usually in the form of little spring tabs that hold the electrical cable snug once it's inserted into the box. Many do not, though, and require the wire to be stapled in place within eight inches of the box. By contrast, many metal boxes require a separate cable clamp that is secured to the cable and then to the box. There's nothing wrong with a separate clamp; it's just easier and a bit quicker to use the plastic tabs.

Plastic is cheaper than metal. Both are pretty cheap, but plastic wins in most cases. The fact that plastic boxes usually don't need clamps also saves you a little bit more.

Durability is where plastic junction boxes lose some points. Along with the box being plastic, the nail brackets are also plastic. They are easily broken off when installing a box or when you have to take a box off and reinstall one. Once this bracket clip is damaged or broken off, your mounting options are all but gone.

Also vulnerable on plastic boxes are the two screw holes for installing a switch, outlet, or other device to the box. As with anything plastic, the threads inside the mounting holes are easily stripped if the screws are not installed properly. Quite often, you may be tempted to put any old screw into these holes, but the threads are usually set to a 6-32 thread. If the threads do become stripped, you may be able to still use the box by installing a short drywall screw into the hole, assuming the hole isn’t cracked or damaged. The screw must hold the device firmly in place.

While using a short drywall screw here is a common practice, the National Electrical Code (NEC) does not allow drywall screws to be used for this purpose. Instead, to keep everything up to code, you can re-tap the holes and use a larger 8-32 screw, which is the same screw used in ceiling boxes.

Metal boxes are also more reliable for overall strength. When mounting overhead light fixtures and ceiling fans, use metal boxes specifically designed for those applications. Although there are some plastic boxes that are designed to support these fixtures, it’s hard to have faith in the plastic threads that support a fixture over your head. For heavy fixtures and all ceiling fans, be sure to use boxes with heavy-duty braces or mounting brackets designed for this purpose.

Plastic junction boxes cannot be used with metal conduit, which is required in various installations, such as outdoors or when wiring runs are exposed (not concealed inside wall or ceiling cavities). For surface-mount installations, such as you might have in a garage, utility area, or outbuilding, metal conduit and metal boxes offer the best protection for wiring and devices.

Shanghai Linsky Electrical Co., Ltd.

+86 21 6710 7908

Office Add:Room 1002,#2 Building,Phoenix Creativity Valley,Lane 1588 Huhang Highway, Fengxian,SH

China Factory Add:#29,Lane 1888 Daye Highway,Fengxian,SH

Cambodia Factory Add:Km 10.5, Road 44 turnoff from Road 4, Santea Phip Village, Phum Krous Commune, Samrong Tong District, Kampong Speu Province, Cambodia

Thai Factory Add: 23/2 Rural Road 2026,Muthi 1,Phana Nikhom.

Copyright © Shanghai Linsky Electrical Co., Ltd.

Here you can send us an inquiry concerning general questions

about LINSKY.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.

I AcceptOur site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.

I Accept